- Design & Development

- Mould Manufacturing & Assembly

- Testing & Inspection

- Machinery

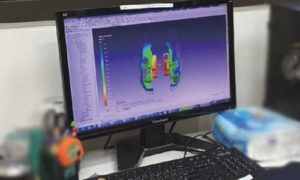

DESIGN & DEVELOPMENT

Nivedya Dies & Tools has the Engineering know-how, Capability and Proven Design Standards to Transform Customer needs into a Superior Product.

On understanding the Customer’s Unique requirements, the Design Process starts. To Implement the Innovative Design thoughts, we use High End Software's AutoCAD. This helps us in Ensuring and Achieving a Superior Final Product.

MOULD MANUFACTURING & ASSEMBLY

Nivedya Dies pride is in State-of-the-Art Manufacturing Facilities that include Fully Automated Machining Line, Comprehensive Production Capacity.

The actual Manufacturing Process runs through many phases, during which we Meticulously observe even the smallest of details.

The Complete Manufacturing Process takes place in Controlled Atmosphere. A Quality Protocol Monitors each of these several steps. The Accuracy of all Machining Operation is Checked Frequently. The Assembly of the Parts into the Finished Mould are followed by the first test to ensure that Moulds Fulfills its Function Perfectly.

TESTING & INSPECTION

Under Our Processing each and every Component that goes in to the Moulds are Inspected at every stage and in Assembly, taking in house Facility to test the Moulds are able to establish Better Quality and Cycle time with Accurate and Precise Inspected Equipments.

Under Our Processing each and every Component that goes in to the Moulds are Inspected at every stage and in Assembly, taking in house Facility to test the Moulds are able to establish Better Quality and Cycle time with Accurate and Precise Inspected Equipments.

Perfect Functioning of the Moulds is in fore ground right from the outset. In our very Well-Equipped Testing Facility each Mould is Systematically tested for High Performance on Modern Injection Moulding Machine.

We at Nivedya Dies & Tools are totally Committed to Quality in all are as of the Business, Quality and Delivery here been the Key Factor which have Contributed to the Development of the Enterprise.

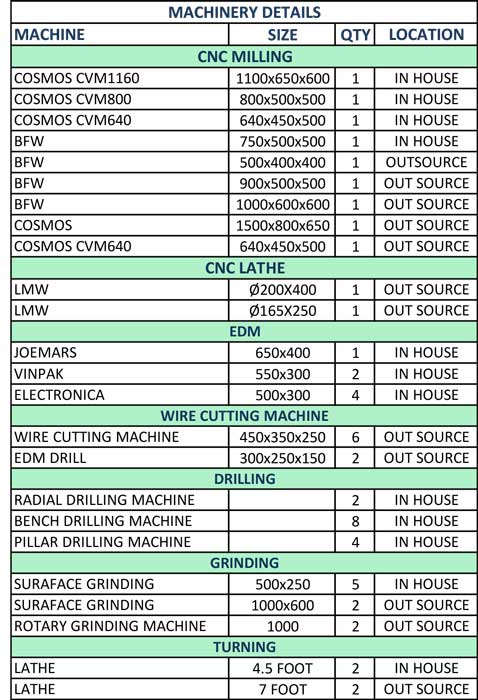

OUR MACHINERIES

Please find below list of Machines for the Mould Base Manufacturing Unit.